Product Features

Straight to Quality

Backed by years of expertise and proprietary technology, we deliver high-quality, cost-effective drive shafts.

Our integrated production—from material selection to straightening, precision cutting, and OD grinding—ensures exceptional straightness and coaxiality.

Designed for long-term use, our shafts offer excellent vibration damping, helping prevent vibration-related conditions such as white finger disease and promoting user health.

Renowned for their quality, Suehiro’s brush cutter drive shafts hold a strong market presence both in Japan and abroad.

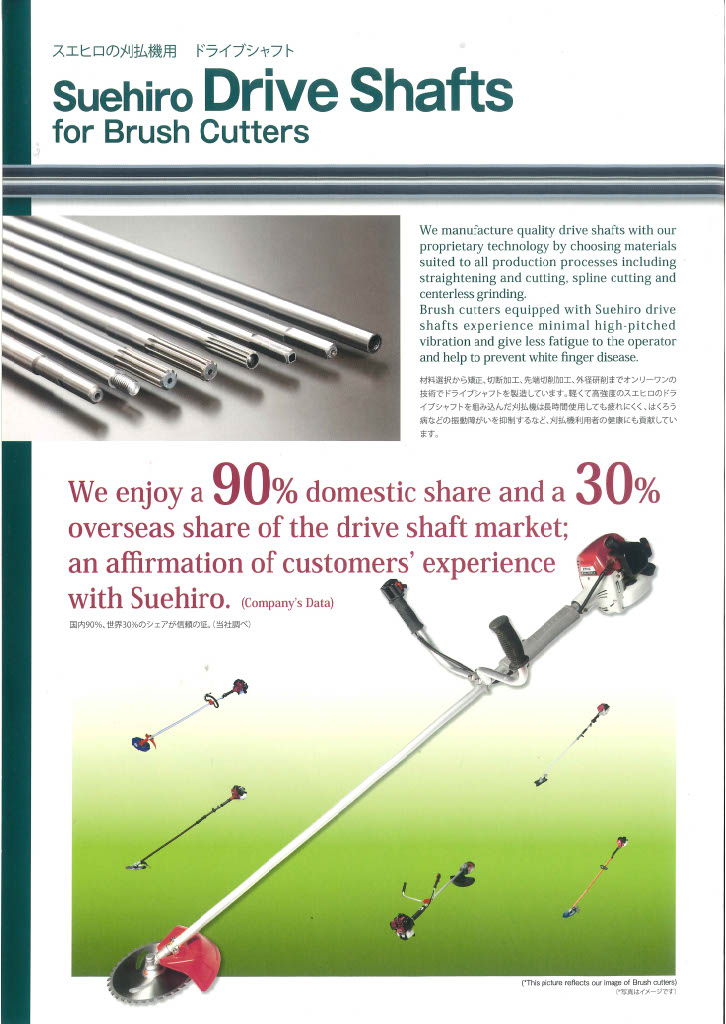

| Supported Steel Grades | High-hardness materials such as S48C, STKM17C, SWRH62B, and others. |

|---|---|

| Supported Dimensions | Outer Diameter: Φ5.5 – Φ11 mm Total Length: 100 – 2,500 mm |

| Straightness | 0.2 mm / 650 mm (Standard) |

| Roundness | Within one-third of the specified outer diameter tolerance |

Product Features

Two-Thirds the Weight of Aluminum, with Metal-Like Strength

Using Suehiro’s proprietary technology, CFRP is molded into a tubular structure—rather than a flat sheet—and was introduced in 1994 as the WESTON® outer pipe for brush cutters.

Weston delivers strength comparable to conventional materials at just two-thirds the weight of aluminum.

Enhanced with specially developed organic fibers, it offers superior durability and significantly improved vibration damping, reducing physical strain during extended use.