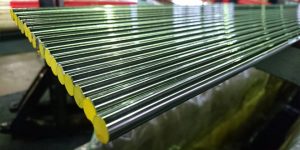

Maximum Length: 4000L | Maximum Diameter: φ50

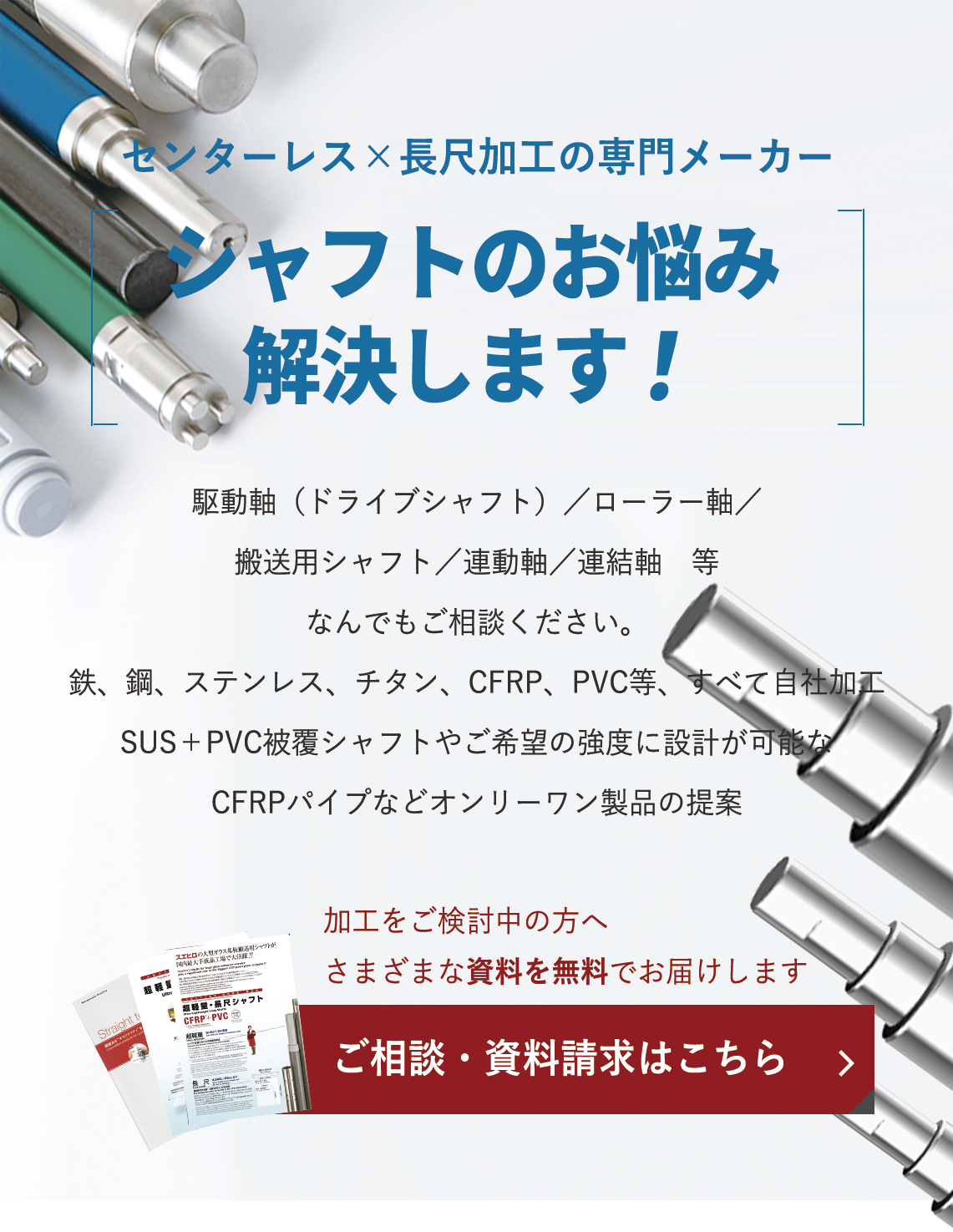

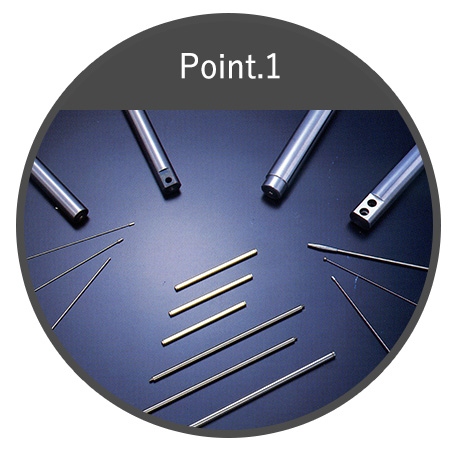

We manufacture a wide range of shafts, including drive shafts, roller shafts, conveyor shafts, linkage shafts, and coupling shafts.

Our in-house processing handles various materials, including iron, steel, stainless steel, titanium, CFRP (Carbon Fiber Reinforced Plastic), and PVC (Polyvinyl Chloride).

We also provide custom solutions, such as SUS + PVC-coated shafts and CFRP pipes, designed to meet your specific strength requirements.

Commitment to the Quality

Made in JAPAN Quality

- All Suehiro Kogyo products are made from Japanese materials and manufactured entirely in-house in Japan. We ensure consistent quality in compliance with ISO standards, with full-length precision guaranteed by our through-feed grinding technology.

Centerless Grinding

- We offer simultaneous processing of lengths up to 4000mm for diameters up to Φ50, and up to 3000mm for diameters under Φ10.

- After shaft turning, centerless grinding is used to reduce outer diameter, remove burrs, and prevent handling damage.

Our experienced operators apply advanced techniques to correct distortion with precision.

Material Design Tailored to Customer Needs

- We leverage our extensive supplier network to design and source materials tailored to customer needs. We also offer processing similar to round bars. For diameters up to φ10, our in-house coil-to-bar straightening ensures superior precision.

Leave your challenges to us!

Design Shafts Tailored to Your Requirements

×

Various Material Combinations

×

Suehiro Kogyo, The Shafts Expert

Uncompromising Commitment to Quality

Our deep expertise in material properties enables robust anti-corrosion protection for steel.

With over 50% of our products exported and a claim rate under 0.1%, we are trusted globally.

Three Key Strengths of Suehiro Kogyo

Versatility

We manufacture shafts from a wide range of materials, including metals like carbon steel, stainless steel, and titanium, as well as resin-based materials such as CFRP, PVC, and engineering plastics. Our expertise extends to processing round bars, pipes, and composite materials to meet diverse requirements.

Custom Design

We provide optimized designs tailored to customer requirements, covering everything from material selection to packaging specifications.

Customer Trust

With over 60 years of commitment to quality, we have earned customer trust through advanced technology and extensive expertise. ISO 9001 certified since 2003.

Technology Overview

Straightening, Cutting, and Distortion Correction Technology

Achieving high precision with straightness of 0.1/1000mm.

Long-Length and Precision Machining Technology

Maintaining perfect straightness for shafts up to φ50 in diameter and 4000mm in length.

Centerless Grinding Technology

Achieving roundness of 0.02 and surface roughness of Ra0.4, with precision down to the micron level.

Material Technology

We offer material design tailored to specific applications, including resin processing of FRP/CFRP, as well as a wide range of steel and carbon materials.

Suehiro Products

From heavy machinery to home appliances, Suehiro can produce drill rods which are customized to meet each customer’s needs.

Exceptional quality of Suehiro’s drive shafts actualizes strong market share and business growth of brush cutters.

We custom-make shafts tailored to the operating environment and purposes.

FRP products, primarily made from CFRP, are super-light and durable. They are good for outer pipes of various machinery.

Guided by our founder’s philosophy of ‘actively embracing new technologies,’ we are dedicated to exploring innovative materials and expanding into new fields of work.