Commitment to Preserving and Advancing Suehiro’s Technology

Advanced technology is never created overnight; it is the outcome of continuous development and refinement over time, passed down through generations.

The Japanese dedication to constant improvement has been a driving force behind the nation’s manufacturing success. Suehiro Kogyo’s technology builds on this deep-rooted tradition of progress. Our manufacturing teams embrace the principle of “never taking our work for granted.”

Even when producing the same products daily, we continuously ask: How can we streamline the process? How can we enhance safety? How can we save time? This mindset of “how can we make it better?” has been the foundation of our technological advancements and quality control.

By incorporating these insights into our production process, we aim to pass these innovations on to the next generation, fulfilling our mission as engineers.

Product Technology #1

“Straightening Technology”

We produce high-precision products with a straightness of 0.1/1000mm.

While the standard straightness is 0.1/1000mm, we can also accommodate ultra-high-precision products with a straightness of 0.05/1000mm for special specifications.

Manufacturing shafts for brush cutters (lawnmowers, grass trimmers) and conveyor shafts used in production lines requires products that are perfectly round and straight. This is a battle against the natural tendency of steel to bend.

To achieve the required precision, we rely on specially improved equipment and the expertise to operate it. Ultimately, human hands play a critical role in producing consistently high-quality results. Even in an increasingly automated and high-tech manufacturing environment, the skilled manual work that Suehiro Kogyo has honed over time is the key to producing products that exceed the standard specifications.

Specifications:

[Standard] Outer diameter φ1.0~φ12.0, straightness: 0.1/1000mm

[Special Specifications] Individual consultation

Product Technology #2

“Long-Length, Precision Machining Technology”

"Long-length Suehiro" is a technology that truly represents Suehiro Kogyo, as many customers associate the company with this capability.

Even for products as long as 4000mm, we achieve straightness of 0.1/1000L or better.

As products become longer, they are more affected by their own weight and other factors, making it increasingly difficult to maintain straightness, a characteristic inherent in steel. However, there is a growing demand for shafts with extremely high straightness, such as those used in large LCD panel production lines, and Suehiro’s one-of-a-kind technology plays a crucial role in these applications.

In brush cutter components, straightness and coaxiality are closely related to vibration suppression and energy loss, making the use of Suehiro-quality parts a fundamental requirement for certain products.

Specifications:

● Straightness: 0.1/1000mm

● Outer Diameter: Up to Φ50.0

● Length: Up to 4000L

Product Technology #3

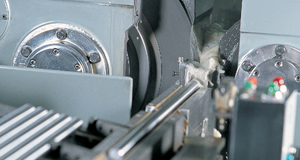

“Centerless Grinding Technology”

Centerless grinding is the most historical and foundational business for Suehiro Kogyo, dating back to its inception.

This technology determines the outer diameter tolerance, straightness, roundness, and surface roughness, all of which directly affect the performance of the shafts as parts.

We manufacture products with micron-level precision using a variety of materials, including metals, non-ferrous metals, FRP, PVC, and other materials with different hardness levels.

While achieving standard precision is possible with the right equipment, some special processes beyond numerical control are essential for achieving Suehiro quality. This is where skilled human expertise plays a crucial role in refining the final product.

Specifications:

● Outer Diameter: φ0.3–Φ60.0

● Length: Up to 7000L

| Outer diameter tolerance | Roundness (Out-of-roundness) | Surface roughness | |

|---|---|---|---|

| Standard | h7・h6 | One-third of the outer diameter tolerance | Rz 3.2 |

| Ra 0.8 | |||

| Special specifications | h5 | 0.002 | Rz 0.4 |

| (Excluding 20L from one end) | Ra 0.2 |

Product Technology #4

“Material Technology”

Quality products are made of quality raw materials.

Since the characteristics of metals can significantly change with the composition of their elements, selection of materials is critical to balance strength and hardness or toughness after heat treatment. For CFRP (Carbon Fiber-Reinforced Plastic) products, we customize the design according to customer requirements tailored to specific applications.

We procure optimal materials for different applications. When we first succeeded in mass-producing pipe shafts for brush cutters, we repeated test productions working closely with raw material suppliers until we find the optimal materials to meet the required tensile strength while minimizing vibration—perfectly suited to the final product.

This is an example of Suehiro Kogyo’ material technology, made possible by our knowledgeable purchasing staff and a network with suppliers built over 60 years of experience.